MANILA

Telefax : (02) 584- 4336

CEBU

Telefax : (032) 345 3374

Telephone : (032) 345 2383

(032) 420 7161

MINDANAO

Telephone : (088) 567 0068

Cellphone : 092-285-06010

KRYPTON INTERNATIONAL

RESOURCES SALES & SERVICES, INC.

Providing industry solution at its best...

POLYMER PRODUCTS

Conveyor Belt Scraper/Cleaner

Features

-

High wear-resistant material

-

Long product life 3-10 times higher than tranditional metal mesh

-

High opening rate and efficiency

-

Reduce noise and vibration

Polyurethane Dewatering Screen

Dewatering Screens are designed to produce a consistent drip-free product, which is typically 10 percent drier than a Fine Material Screw Washer. Materials such as sand, gravel, crushed aggregates, frac sand, industrial sands, mineral sands, hard rock, precious metals, coal, iron ore, salt and other granular materials can be processed through a Dewatering Screen.

To dewater material effectively, slurry is fed onto a steep, downward inclined screen surface at the feed end of the Dewatering Screen to achieve rapid drainage. A pool of water begins to form in the valley as material builds up on the slightly upward inclined surface. Counter rotating motors create a linear motion, driving solids uphill, while liquid drains through the screen media. The uphill slope of the screen, along with a discharge weir, creates a deep bed that acts as a filter medium, allowing retention of material much finer than the screen openings. Where cleaner materials are required, cross dams and sprays can be included to assist with the washing process, liberating fines that pass through the media.

Our Advancement

Resources Unity enhanced the original concept with a redesigned structural frame under the deck to include cross beams that make the machine easier to maintain. This design is suspended on rubber buffers rather than springs for improved wet performance. Resources Unity also custom engineers screen media, which is produced in-house, for heavy-duty applications.

High Frequency - Ultra Fine

High frequency fine screens have long product life providing customers with confidence and maximum operational efficiency.

Benefits

Product is computer generated and designed, and production process is controlled by computerised system to ensure all spares free of issue from installation.

Effective design function for productivity and/or product life in according to customer’s needs to improve overall value.

Custom make products are available upon request.

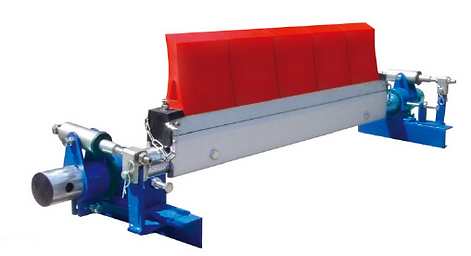

Conveyor Belt Scraper/Cleaner

Belt Cleaner Blade

(Standard)

Belt Cleaner Blade

(Thin)

Belt Cleaner Blade (H-Duty)

Scraper Blade

(Stainless Steel Seat)

Typically, conveyor belt cleaning system is one or more scrapers mounted at or near the discharge (head) pulley to remove residual fines.

Engineered belt scraper system consists of a structural support (mainframe), cleaning element (blade), and tensioner. Simple and fast blade replacement will reduce maintenance and labour requirements.

The conveyor belt cleaning system can also come with:

Ceramic or Tungsten Blades with Boron Carbide insert for longer life.

Multi-blade construction allows individual blade to deflect or minor obstructions and adapt to belt profile.

Chute side mountings for easy adjustment

Belt Cleaner Blade

(Heavy Duty)